Amazon supply chain management is a comprehensive and automated set of services that facilitates the movement of products from manufacturers to customers worldwide. This system ensures products are always in stock, enables faster and more reliable shipping, and significantly reduces costs.

In this article, we’ll explain how Amazon supply chain works, the 5 key elements contributing to Amazon’s success, and compare 2 primary Amazon supply chain management FBA vs FBM. But before digging to deepen your understanding of Amazon supply chain management, here are two key takeaways:

- Amazon designs its supply chain with the customer in mind, prioritizing speed, accuracy, and satisfaction.

- Robotics and automated systems are heavily used throughout Amazon’s supply chain.

Let’s get to the details!

Manage your Inventory and Save Time with LitCommerce

Struggling to juggle multiple channels and keep your inventory in check? LitCommerce is an excellent solution. This all-in-one platform helps you save time by centralizing channel management and inventory control.

What is mazon Supply Chain?

Amazon Supply Chain is an entire process of automated services that help sellers manage their supply chains and get products to customers worldwide. The method includes inventory management, warehousing, pricing, and delivery.

Using Amazon supply chain, sellers can enjoy faster and more reliable shipping and automatically replenish inventory to the correct Amazon fulfillment centers, further streamlining supply chain management.

How Does Amazon Supply Chain Work?

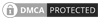

Amazon has one of the world’s most sophisticated supply chain operations, which benefits both Amazon itself and the third-party sellers on its marketplace. To understand how does Amazon supply chain works, you can look at the diagram to best visualize how Amazon’s logistics works:

Our focus will now shift to a detailed examination of each step:

Receive products from sellers

Amazon Supply Chain begins with the crucial step of receiving products from sellers. However, only FBA seller can send their products in bulk to Amazon fulfillment centers. It is vital to note that FBA seller can’t deliver their inventory directly to the nearest FBA warehouse. Only professional carriers are allowed to make delivery appointments with Amazon Fulfillment Centers.

It should be noted that:

- For global sellers: Shipping to the Amazon Fulfillment center is handled by Amazon Global Logistics.

- For domestic sellers: Amazon Sponsored Program Carrier Program is responsible.

Upon arrival, products undergo a meticulous process of receiving to check if they are accurate, of high quality, and in compliance with Amazon’s standards. Then, advanced barcode scanning and inventory management systems accurately log the products into Amazon’s vast inventory.

Store and distribute inventory

These fulfillment centers are designed to optimize storage space and facilitate the smooth movement of inventory.

Amazon utilizes advanced robotics and automation to manage its inventory. Robots assist in the movement and retrieval of products within the fulfillment centers. This advanced technology enables Amazon to maximize efficiency and minimize the time it takes to fulfill customer orders. Amazon uses smart robots and computers to manage its warehouses. These robots help find and move products quickly, so Amazon can get orders to customers faster.

Robots assist in the movement and retrieval of products, significantly reducing the time it takes to fulfill customer orders. They transport items across the warehouse, which minimizes the need for human workers to walk long distances—previously, workers could walk 10 to 15 miles a day, but with robots, this is reduced by 75-80%. Effectively using robots requires sellers to manage inventory well, a time-consuming task due to the large number of SKUs.

Fulfill customer orders

Fulfilling customer orders is a critical stage of Amazon Supply Chain Management. Amazon’s sophisticated fulfillment system goes into action:

Customers browse Amazon’s website or app, select products, and proceed to checkout. Once the order is confirmed, it is entered into Amazon’s order management system.

After an order is placed, it is routed to the seller’s Amazon Seller Central account. Sellers receive notifications of new orders and begin processing them by:

- Confirming inventory availability

- Preparing products for shipment

- Creating shipping labels

The seller then chooses between different fulfillment methods:

- Fulfillment by Amazon (FBA): sellers send their products to Amazon’s fulfillment centers, where Amazon handles storage, packing, shipping, customer service, and returns.

- Fulfillment by Merchant (FBM): sellers manage all aspects of order fulfillment themselves, including storage, packing, and shipping.

- Seller Fulfilled Prime (SFP): Similar to FBM, sellers must meet specific Prime delivery requirements while fulfilling orders themselves.

- Multi-Channel Fulfillment (MCF): this option allows sellers to use Amazon’s fulfillment centers to fulfill orders from other sales channels, such as their own websites.

Once the order is processed, it is shipped using the chosen carrier. Amazon provides tracking information to customers, allowing them to monitor their orders until delivery.

The order management cycle concludes when the order is successfully delivered. Sellers may follow up with customers for feedback or handle any return processes as needed.

Deal with order return

To complete Amazon Supply Chain Management, the company has implemented a streamlined and customer-friendly returns process to ensure a positive experience for its customers.

When a customer initiates a return, Amazon’s system generates a pre-paid return label and provides instructions for the return.

- Customers can choose to drop off the return at a designated location or have it picked up by a carrier.

- Once the return arrives at the fulfillment center, it undergoes a thorough inspection to determine its condition and eligibility for resale.

Moreover, Amazon uses sophisticated algorithms and processes to check returned items and decide if they can be resold, fixed up, or thrown away.

5 Key Factors of Amazon Supply Chain Management

To take full advantage of the power of the Amazon supply chain process, you need to understand the following six key aspects:

- Warehousing

- Delivery

- Technology

- Pricing

- International reach

1. Warehousing

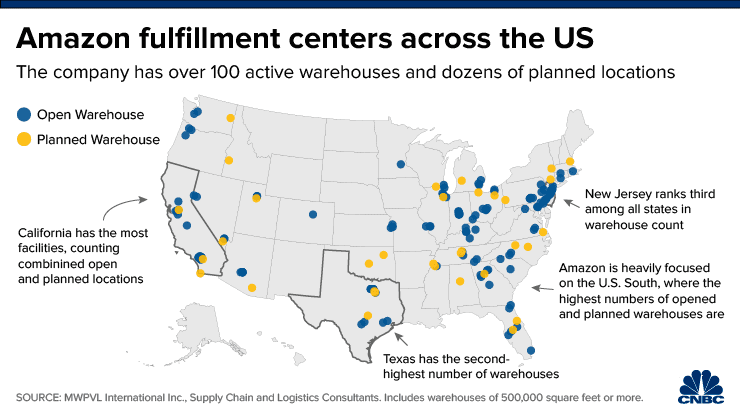

The warehouse system is a crucial component of Amazon Supply Chain Management. It is a complex network of facilities designed to get items to customers as quickly and efficiently as possible. Amazon facilities are typically at least 100,000 square feet in size and house all kinds of product inventory.

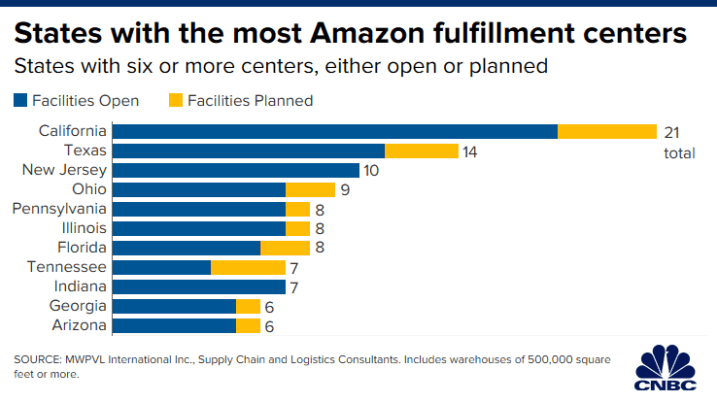

Remarkably, Amazon enforces strict standardization across its warehouse system. This ensures a consistent experience for employees and customers, regardless of location. They have opened the most fulfillment centers in California and appear to be planning many future locations across the southern US.

Moreover, Amazon divides the distribution network into five types of facilities, including cross-dock centers and fulfillment centers. Here’s a breakdown of the key aspects:

- Fulfillment centers: these are massive warehouses that store a wide variety of products. When a customer places an order, items are picked from the shelves here and prepared for shipping.

- Sortation centers: Sortable fulfillment centers, around 800,000 square feet in size, can employ more than 1,500 full-time associates. In this building, Amazon packages from fulfillment centers are delivered, sorted by destination, and loaded onto trucks for delivery.

- Non-sortable: Fulfillment centers that cannot be sorted can range in size from 600,000 to a million square feet and have over a thousand full-time employees. These structures house Amazon associates’ picking, packing, and shipping of large or bulky client items like carpets, patio furniture, and outdoor equipment.

- Delivery stations: these are smaller facilities located closer to final destinations. Packages are delivered here from sortation centers and loaded onto vans for final delivery to customers.

- Prime Now Hubs: these hubs are specifically designed for Amazon’s ultrafast Prime Now delivery service. They store a limited selection of high-demand products for near-instant delivery.

- Amazon’s receive centers support customer fulfillment by taking in large orders of the types of inventory that quickly sell and portioning it out to fulfillment centers within the network. Full- and part-time roles are available in these buildings, which are about 600,000 square feet in size.

2. Delivery

Amazon’s commitment to fast and reliable delivery is a cornerstone of its Amazon Supply Chain Management strategy. Here are some highlight points related to Amazon’s delivery strategy:

AMZL: Amazon Logistics (AMZL) is Amazon’s in-house delivery service that handles the “last mile” delivery of Amazon packages, meaning they transport the order from the warehouse to the specified delivery location. AMZL is responsible for shipping roughly 46% of Amazon’s packages. Even more compelling is

Amazon doesn’t just rely on trucks! Their growing fleet of cargo planes, called Amazon Air. They are used to speed up deliveries by flying packages directly between fulfillment centers.

AMZ has invested in air cargo services at over 15 US airports, with each jet transporting more than 30 containers. That’s why in 2022, Amazon Logistics processed 4.79 billion U.S. delivery orders, equating to 13.13 million delivery orders per day or 546,941 per hour (According to Capital One Shopping).

- Other carriers such as UPS, FedEx, and the United States Postal Services (USPS)

- A network of independent contractors through Amazon Flex

- Amazon Delivery Service Partners, which operates fleets of delivery vans

3. Technology

Technology plays a pivotal role in Amazon Supply Chain Management. Let’s take a look at some state-of-the-art technology being applied:

Robotic automation: Amazon heavily invests in robotics within its fulfillment centers. Robots handle repetitive tasks like product picking and movement, significantly increasing efficiency and accuracy. CMO Leavitt used to say, using robots, “we are doubling or even tripling the productivity of the humans in that warehouse, and we’re cutting down on the amount of walking they do by probably 75 or 80%”.

Some of the legends in Amazon’s robot system include:

- Sparrow: It is a smaller robot arm that can reach into totes and reliably grasp 65% of the more than 100 million products in Amazon’s inventory.

- Kiva robots: These are short, orange robots that move shelving units around the warehouse floor and bring them to pickers.Technology plays a pivotal role in Amazon Supply Chain Management.

- Mobile robots: These are considered the workhorses of Amazon’s warehouses.

Air capabilities: While ground transportation forms the backbone of Amazon’s delivery network, air freight plays a crucial role in ensuring fast delivery times for certain products and locations:

- Amazon Air: The company has invested heavily in its fleet of cargo planes, which allows it to control delivery schedules and transport time-sensitive items faster.

- Prime Air: Amazon is also developing drone delivery systems (Prime Air) for short-distance deliveries in specific areas. This futuristic technology may revolutionize delivery times in urban areas.

Data analysis: Data is the lifeblood of Amazon’s supply chain. This platform uses machine learning algorithms to make data-driven decisions for tasks like:

- Demand forecasting: By analyzing past sales data and identifying trends, Amazon can more accurately predict future product demand.

- Route optimization: Delivery routes can be optimized based on factors like traffic patterns, weather conditions, and driver availability.

- Warehouse layout: Data analysis can be used to optimize warehouse layouts for better product placement and picking efficiency

4. Pricing

Pricing strategy is a key driver of Amazon Supply Chain Management. Amazon’s pricing policy enables you to segment customers into two groups:

- Prime: Members in this group pay $14.99/month (plus tax) and receive fast, free delivery. They also get some benefits like exclusive deals and free access to popular movies, shows, music, games, and books.

- Standard: These clients can use only standard or slower delivery.

Understand that segmentation allows sellers and Amazon to respond instantly to fluctuations in demand. It also correctly calculates the order flow and ensures the efficiency of Amazon Supply Chain Management.

On the other hand, pricing factors also affect the supply chain for FBA sellers. Amazon imposes long-term storage fees on items that remain in their fulfillment centers for extended periods. These fees can significantly impact a seller’s profitability. As a result, FBA sellers need to carefully predict future demand to avoid excess inventory and the associated costs.

5. International reach

The final component that strongly affects supply chain of Amazon is global reach. With operations in multiple countries, Amazon has established a robust network of suppliers, fulfillment centers, and delivery partners to serve diverse markets worldwide.

As an Amazon seller, you benefit greatly from this extensive network. With Amazon’s timely and efficient delivery options, sellers can expand their businesses globally. Check out the list below to see which markets Amazon has entered:

North America:

- United State (amazon.com)

- Canada (amazon.ca)

- Mexico (amazon.com.mx)

Europe:

- United Kingdom (Amazon.co.uk)

- Germany (Amazon.de)

- France (Amazon.fr)

- Italy (Amazon.it)

- Spain (Amazon.es)

- Netherlands (Amazon.nl)

- Sweden (Amazon.se)

- Poland (Amazon.pl)

- Turkey (Amazon.com.tr)

Asia:

- Japan (amazon.co.jp)

- Mumbai (amazon.in)

- Singapore (amazon.sg)

Middle East:

- United Arab Emirates (amazon.ae)

- Saudi Arabia (amazon.sa)

- Egypt (amazon.eg)

Other:

- Australia (amazon.com.au)

- Brazil (amazon.br)

Amazon Supply Chain Models: FBA and FBM

Amazon has one of the world’s most sophisticated supply chain operations, which benefits both Amazon itself and the third-party sellers on its marketplace. You can choose one of the

Keep scrolling for a detailed breakdown of what the Amazon supply chain entails!

FBA (Fulfilled by Amazon)

FBA refers to a program offered by Amazon that allows sellers to store their products in Amazon’s fulfillment centers. When a customer places an order, Amazon takes care of the entire fulfillment process (Picking, packing, shipping, and customer service).

Pros and cons of this Amazon supply chain strategy:

- Pros:

- Convenience: Amazon handles everything from storage and picking & packing to shipping and customer service.

- Faster delivery times: Amazon’s fulfillment network often leads to faster shipping and increased customer satisfaction.

- Prime eligibility: Amazon’s products fulfilled are automatically eligible for Prime-free two-day shipping.

- Increased sales potential: FBA sellers often get better product placement and win the “Buy Box” more frequently, which can lead to more sales.

- Cons:

- Fees: FBA comes with several fees, including fulfillment fees, storage fees, and potential removal fees. These fees can eat into your profit margins.

- Less control: You have less control over the fulfillment process with FBA.

FBM (Fulfilled by Merchant)

Unlike FBA, FBM allows sellers to fulfill customer orders themselves. When using this Amazon Supply Chain strategy, sellers are responsible for storing, packaging, and shipping their products directly to customers.

Pros and cons of FBM:

- Pros:

- Greater control over branding: You have complete control over the packaging and presentation of your products. Thus, you can maintain a strong brand identity.

- Potentially lower costs: For sellers with high-volume or bulky items, using FBM can be more cost-effective compared to FBA storage fees.

- Direct inventory control: You have complete control over your inventory levels and can monitor stock more closely to avoid stockouts.

- Cons:

- Slower shipping times: Unless you have a robust fulfillment infrastructure in place, FBM can lead to slower shipping times compared to FBA.

- Increased operational complexity: Managing your fulfillment requires significant time, resources, and expertise. This can be a burden for smaller sellers or those with limited resources.

- Customer service: You are responsible for handling all customer service inquiries related to fulfillment. This task can be time-consuming and requires dedicated staff

Discover the benefits and drawbacks of both fulfillment methods to choose the optimal one. Check our detailed comparison guide at Amazon FBA vs FBM: Which One is Right for Your Business Model?

Amazon Supply Chain Management: FAQs

The Amazon Supply Chain is highly efficient, thanks to continuous optimization, embracing technology, and fulfillment strategies. Amazon’s use of advanced technology, extensive network of warehouses, multi-tier inventory management, and excellent transportation contribute to its efficiency. The company’s investments in infrastructure, such as warehouse technology and trucking capabilities, further enhance efficiency The Amazon Supply Chain is successful due to a three-pronged approach: tech, efficiency, and scale. They leverage automation with robots and AI for tasks like order picking and inventory management. This focus on efficiency extends to their vast network of fulfillment centers, strategically placed to get products to customers quickly. Finally, the massive scale of their operation allows them to negotiate better deals with suppliers and carriers, further driving efficiency. Amazon’s supply chain relies heavily on automation. It uses robots, conveyor belts, and other technologies to sort, store, and ship products efficiently. This allows it to handle large volumes of orders quickly and keep costs down. Amazon is also developing AI-powered tools for planning and managing inventory. Amazon’s supply chain is known for being fast and reliable, and the company uses a combination of traditional and innovative tools to manage it including Technology: Amazon uses robots, artificial intelligence, machine learning, and automated conveyor belts to streamline its fulfillment centers. Its ecosystem of interconnected systems, including data centers, distribution networks, and retail storefronts, enables it to collect and analyze vast amounts of data.

Amazon Supply Chain Management: Final Words

Amazon’s unrivaled efficiency, speed, and customer-centric approach have set the bar high for the supply chain. Furthermore, if the idea of selling on multiple channels simultaneously resonates with you, feel free to reach out to us for expert guidance on utilizing LitCommerce tools. Plus, stay ahead in the industry by exploring my Retail Blog, where you can discover the latest trends and invaluable strategies for enhancing your eCommerce business.